NDT/Inspection Services

Our NDT workforce consists of certified professionals with deep expertise in testing techniques like UT, RT, MT, PT, and PWHT. With hands-on experience and a strong commitment to safety, precision, and quality, they ensure asset integrity across industries without causing damage or disruption.

Excellence in Inspection & Non Destructive Testing

Industry-leading NDT/Inspection Services in various methods

.jpg)

Welcome to the NDT Services section of BITS. With a strong foundation established in 2010, BITS has been a trusted provider of comprehensive Non-Destructive Testing services across India.

Our NDT capabilities are essential for ensuring the integrity, safety, and reliability of critical assets in various industries, including mechanical construction, refineries, and petrochemical plants.

Our team of certified and experienced technicians utilizes a range of advanced NDT methods to detect defects, assess material properties, and ensure compliance with industry standards without causing damage to the component or structure being inspected.

We understand the critical importance of accurate and reliable NDT results in preventing failures, extending asset life, and ensuring operational safety.

Our NDT/Inspection Methods

Comprehensive Services in various NDT methods

Radiography Testing

Using X-rays or gamma rays to detect internal flaws in:

- Welds and joints

- Pipeline and Piping

- Pressure Vessels, Heat Exchangers and Other Equipment

- Storage Tanks and Spheres

- Code and standard compliance

Ultrasonic Testing - Thickness Gauging (UT TKY)

Focused on precise thickness measurement to monitor corrosion and erosion.

- Corrosion monitoring

- Material thickness measurement

- Weld inspection

- Flaw detection

- D category in Pressure Vessels

- Lamination Check in plates and pipelines

- Castings, Forgings

- Digitization

- Code compliance and reporting

Magnetic Particle Testing

Detecting surface and near-surface flaws in ferromagnetic materials using magnetic particles.

- Inspection of welds in pipelines and vessels.

- Examination of structural steel components.

- Testing of castings and forgings.

- Applicable across Oil & Gas, power, and manufacturing sectors

- Code compliance and reporting

Liquid Penetrant Testing (PT)

Revealing surface cracks in non-porous materials using liquid penetrant and developer.

- Inspection of welds on non-ferrous pipes and tanks.

- Examination of valves and fittings.

- Testing of components made from aluminum, stainless steel, etc.

- Widely used in petrochemical and general mechanical industries.

- Code compliance and reporting

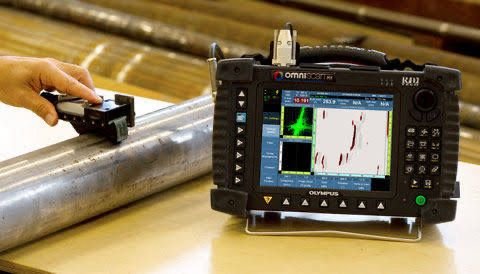

Phased Array Ultrasonic Testing (PAUT)/Time of Flight Diffraction Ultrasonic Testing (TOFD UT)

Advanced ultrasound using multi-element probes for precise flaw imaging and sizing.

- Complex weld inspection in pressure vessels and piping.

- Automated scanning of long seam welds.

- Corrosion mapping and monitoring.

- Critical applications in refineries and power plants.

- Code compliance and reporting

Heat Treatment Services

Heat treatment preserves material properties before or after processes like welding.

- APre and post-weld heat treatment (PWHT).

- Complex Weld in Pressure Vessels and Piping

- Pre Heating for High thinckness before welding

- Localized Heat Treatment

- Temporary Furnace Heat Treatment

- Code compliance and reporting

Specialized Services

Advanced Inspection Services on Demand

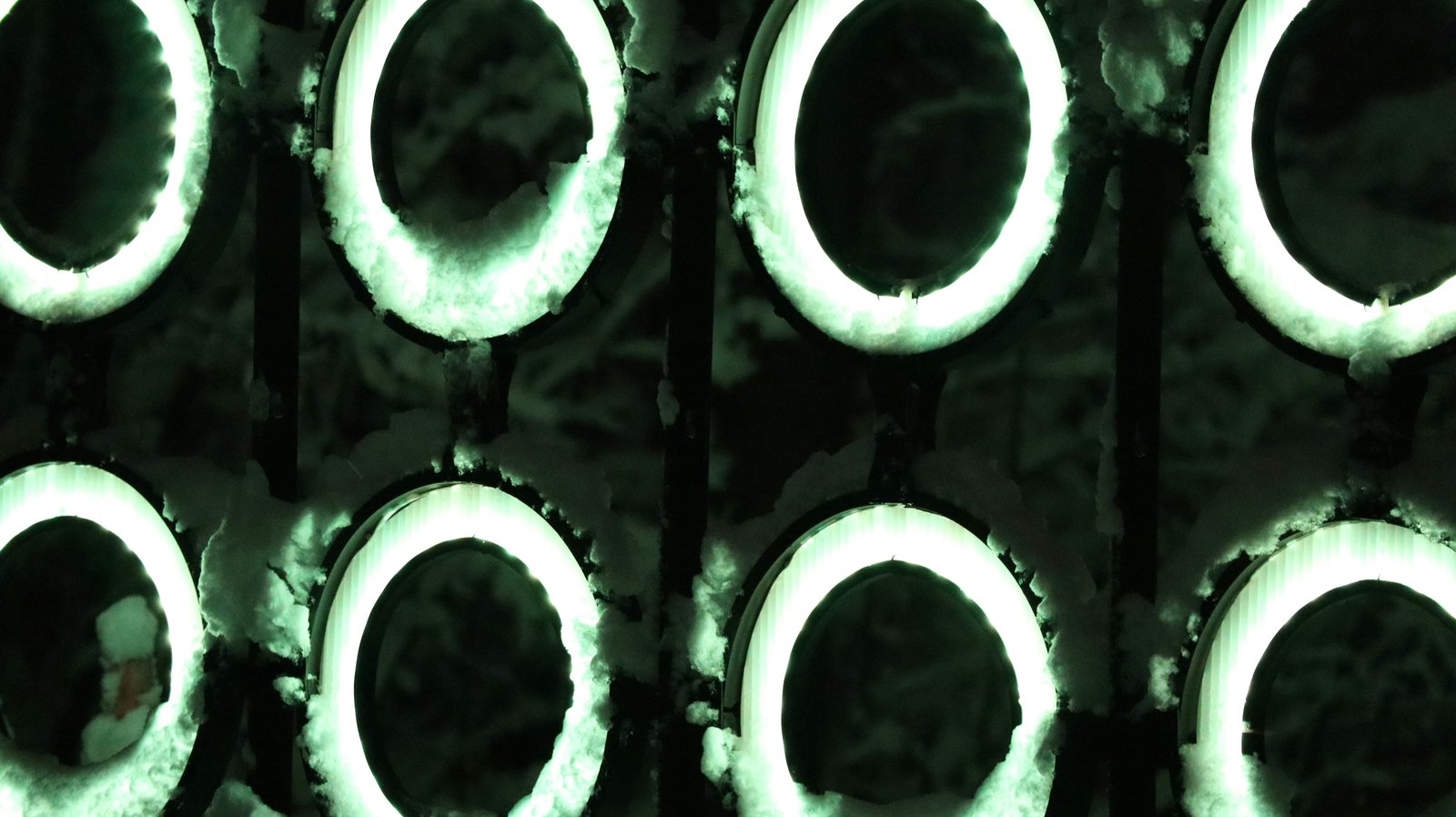

Tube Inspection (IRIS, ECT, MFL, RFET)

Tube inspection for ferrous and non-ferrous materials using IRIS, ECT, MFL, and RFET to detect corrosion, pitting, and cracks in heat exchangers, boilers, and condensers. Ensures code compliance and detailed reporting.

Learn More

Long Range Ultrasonic Testing (LRUT).

Rapid pipeline screening for CUI and hidden defects in buried or elevated piping, minimizing scaffolding/excavation. Flags areas for detailed NDT. Suitable for all pipe sizes. Ensures code compliance and reporting.

Learn More

Magnetic Flux Leakage Testing of Tanks

High-speed inspection of storage tank floors and lower shells to detect corrosion and pitting. Suitable for all tank types, enabling targeted repairs and detailed condition mapping.

Learn More🚀 Tired of jobs?

Start building your career

75% of all our senior managers built their career at Bits Pvt Ltd. Join the team of professionals, innovate and succeed

📞 Get in Touch